The automatic ribbon slitting machine has significantly improved production efficiency through technological innovation

13. June, 2025

As a key equipment in industrial production, the efficiency improvement of slitting machine directly affects cost control and capacity output.

12. June, 2025

Through the humanized design, this barcode ribbon slitting machine greatly reduces the operation threshold and maintenance difficulty, and truly realizes the "slitting worry-free" work experience.

12. June, 2025

By optimizing the maintenance design, downtime can be significantly reduced and overall equipment effectiveness (OEE) can be increased.

12. June, 2025

Through historical data learning, it automatically recommends the combination of slitting parameters to further reduce the loss of trial and error.

11. June, 2025

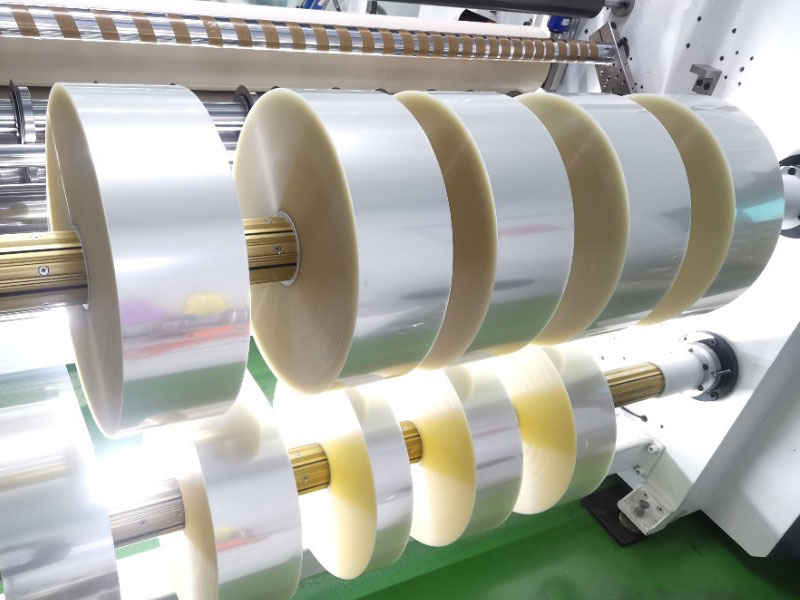

The adaptability of the capacitor film slitting machine needs to be continuously optimized around the material characteristics, terminal application scenarios and intelligent trends.

11. June, 2025

Your need is to find a customized ribbon slitting solution that can flexibly meet the requirements of different ribbon widths.

11. June, 2025

The following is the detailed technical scheme and application analysis of lithium battery separator slitting:

10. June, 2025

The following are the key technical solutions to meet the high-intensity demand:

10. June, 2025

The following are the five typical application scenarios and their specific descriptions:

10. June, 2025